Your backup generators and emergency power systems are precision machines engineered to operate with clean fuel.

Regular fuel maintenance is essential for reliable emergency power and regulatory compliance.

When fuel quality degrades, both your operations and compliance status are at risk.

Our advanced fuel polishing process transforms contaminated fuel into pristine backup power protection, ensuring your critical systems are always ready when you need them most.

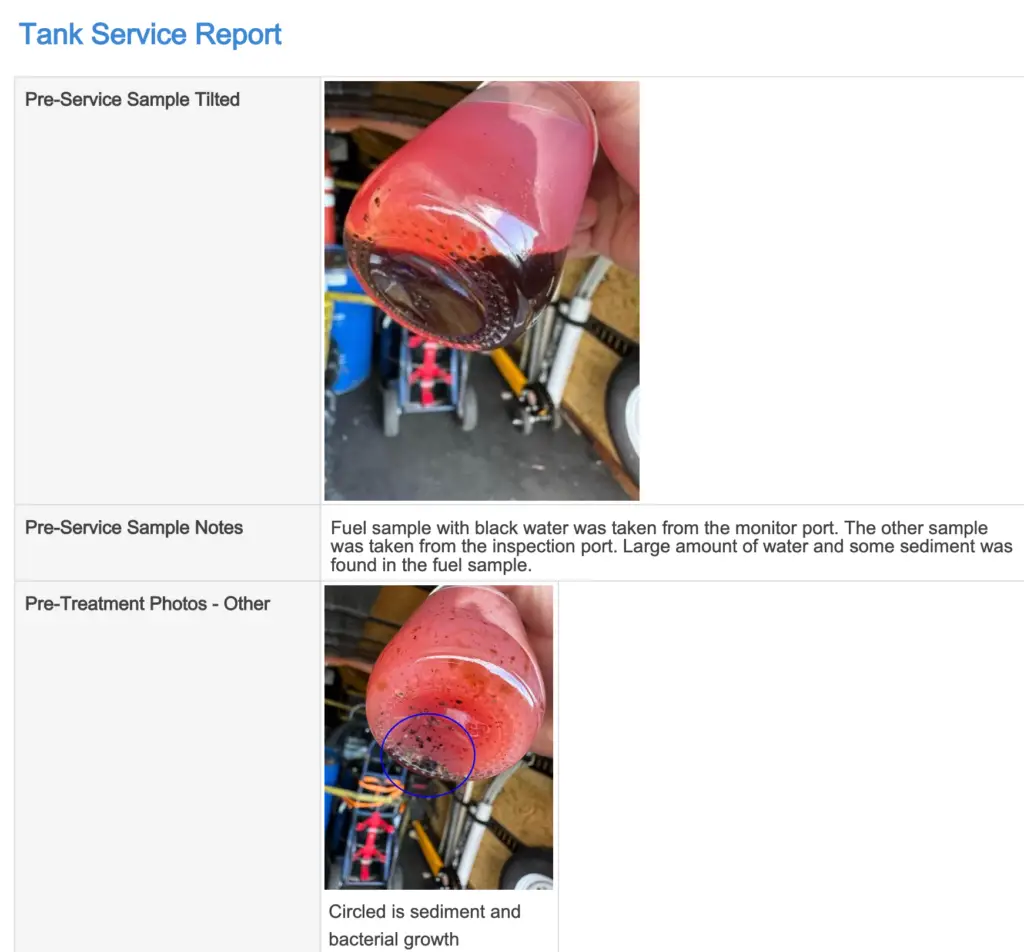

Pre-cleaning sample shows water-sediment mix at bottom of sample jar.

Move slider to show change from pre-cleaning to post-cleaning

Post-cleaning sample shows clean and clear diesel fuel

Modern facilities operate under strict regulatory frameworks that mandate reliable emergency power.

NFPA 110 compliance, JCAHO standards, and CMS requirements establish clear guidelines for backup power systems.

Insurance providers and environmental regulators add additional layers of oversight, making comprehensive fuel maintenance documentation essential.

Critical operations at risk include:

– Hospital emergency power systems

– Data center continuous operations

– Telecommunications infrastructure

– Municipal emergency response systems

– Critical facility operations

Today’s fuel requires significantly more maintenance than in previous decades.

Modern bacterial strains show increased resistance to biocides and thrive in conditions that were previously inhospitable.

This evolution of fuel contaminants makes professional maintenance more critical than ever.

In 2007, environmental regulations fundamentally changed fuel composition.

The removal of sulfur, which had acted as a natural biocide in diesel, and the introduction of ethanol in gasoline created new maintenance challenges.

Modern biodiesel formulations present dual challenges: higher water attraction and increased water retention. These changes have made fuel more susceptible to contamination and bacterial growth.

A 2016 EPA study revealed alarming statistics: 83% of diesel tanks showed moderate to severe corrosion, yet only 25% of tank owners were aware of these issues.

Equipment failures due to fuel degradation continue to rise.

Water infiltration occurs through multiple pathways in fuel storage systems.

Daily temperature changes create condensation in vented tanks, while damaged fittings or vent caps provide direct entry points.

Modern fuel’s higher moisture attraction compounds these issues, making water accumulation a constant challenge.

When water enters a fuel tank, it creates ideal conditions for destructive microorganisms.

These bacteria form colonies at the water-fuel interface, consuming fuel and producing corrosive acids.

The resulting biomass clogs filters and spreads throughout the system, compromising tank integrity.

Once established, these colonies can quickly contaminate new fuel additions, creating a cycle of degradation.

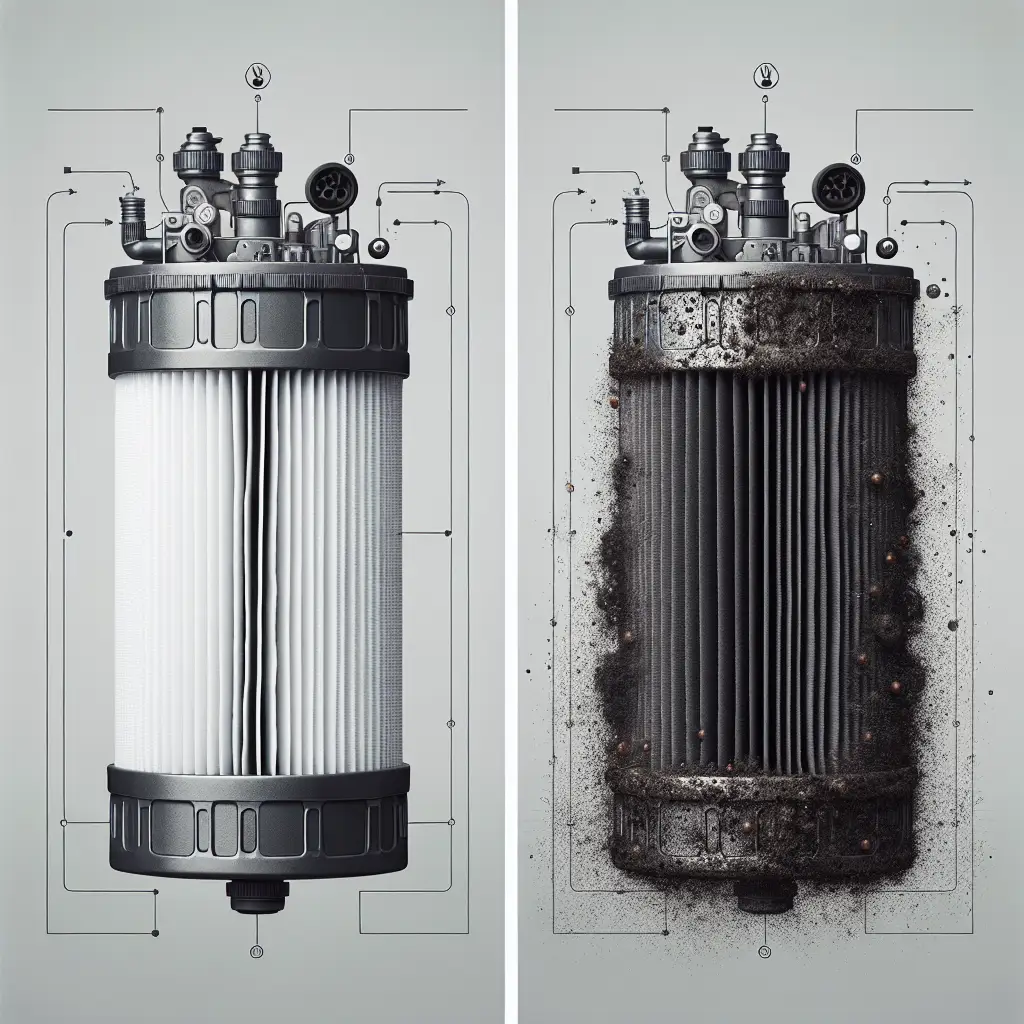

Standard fuel filters provide essential protection but cannot address underlying contamination issues. While necessary, filters quickly become overwhelmed by severe contamination and may restrict critical fuel flow when clogged.

Chemical additives offer temporary solutions but create long-term challenges. Rather than removing water, they disperse it into tiny droplets throughout the fuel. These suspended droplets create widespread bacterial hosting sites, actually making the contamination problem worse while creating a false sense of security.

While automatic polishing systems can help maintain fuel quality, they typically lack the pressure needed for complete tank cleaning. Without sufficient turbulence, they cannot effectively remove accumulated sediment and contamination from tank surfaces.

We begin every service with comprehensive safety planning.

Our team conducts a detailed site assessment, reviews emergency procedures, and coordinates with facility staff to ensure safe, efficient operations.

A typical service takes 4-8 hours, varying based on tank size, contamination level, site access, and system complexity.

Our advanced system operates like a high-pressure dialysis machine for your fuel.

Through multi-stage filtration from 200 down to 1 micron, we remove water, sediment, and contamination while continuously monitoring the process.

High-pressure cleaning ensures thorough tank surface treatment, while specialized water removal systems eliminate contamination sources.

Our commitment to excellence starts with our people.

Every technician undergoes regular background screening and maintains current industry certifications through continuous training.

Our Field Management team provides quality assurance oversight for all services and documentation.

We understand the sensitive nature of critical facilities. Our teams operate within client security protocols, maintain compliance, and follow strict data protection procedures.

We offer flexible scheduling options, including nights and weekends, to minimize operational impact.

Our reporting process ensures you’re informed every step of the way:

Same-Day Communication:

– Immediate notification of urgent issues

– Preliminary contamination assessment

– Initial treatment recommendations

Within 2 Business Days:

– Comprehensive digital service documentation

– Before/after photo evidence

– Complete analysis and recommendations

Laboratory Analysis (7-21 Days):

– Independent third-party testing

– ASTM standards verification

– Detailed contamination analysis

– Regulatory compliance confirmation