Catch fuel issues before they impact your operations

Your emergency power systems rely on one crucial element: clean, reliable fuel.

Even a small amount of contamination can lead to system failure when you need it most.

Modern engines and their sophisticated fuel injection systems are particularly vulnerable to fuel quality issues, making regular testing not just beneficial, but essential.

Your emergency power systems rely on one crucial element: clean, reliable fuel.

Even a small amount of contamination can lead to system failure when you need it most.

Modern engines and their sophisticated fuel injection systems are particularly vulnerable to fuel quality issues, making regular testing not just beneficial, but essential.

Even fuel that starts pristine will degrade over time.

More concerning, introducing clean fuel into a contaminated tank can trigger rapid deterioration – bacteria present in the tank will quickly colonize and contaminate the new fuel.

This creates a cycle of contamination that can only be broken through proper testing and remediation.

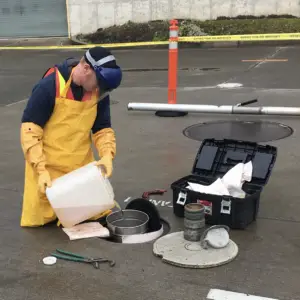

Accurate fuel testing requires both expertise and precision.

Our certified technicians know exactly where and how to draw representative samples, focusing on critical areas such as the lowest point of your tanks where contaminants accumulate.

We understand the complexities of different tank designs and how they affect proper sample collection.

Stored fuel is living chemistry in action.

Without proper maintenance, it creates a cascade of problems that can leave your backup systems vulnerable just when you need them most.

Understanding this process is the first step to preventing it.

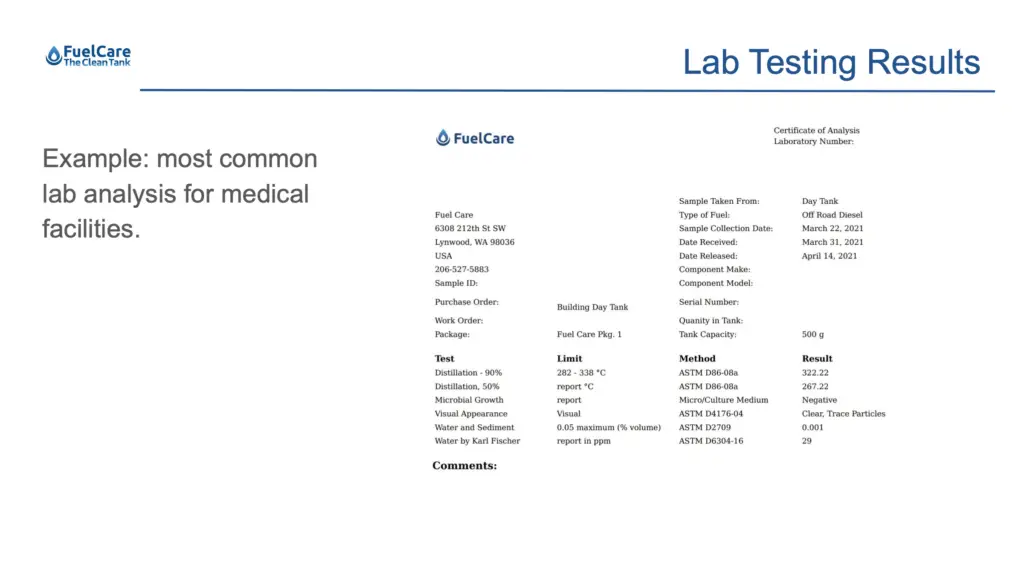

For comprehensive understanding of your fuel quality, we work with independent, third-party labs thorough testing that can include:

Our partnership with accredited laboratories ensures reliable, third-party verified results you can trust.

Fuel problems are common and easily treatable if caught in time.

Select a common fuel concern to see how FuelCare’s can help you

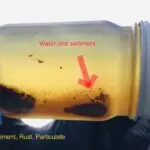

Condensation and environmental exposure lead to water accumulation, causing corrosion and microbial growth that can disable your backup systems.

When water enters fuel tanks, bacteria that live in the water layer feed on the fuel, multiplying rapidly and producing acidic waste that corrodes metal components. As these bacteria colonies grow and die, they create a thick, sticky biomass that settles as sludge, clogging filters and fuel lines while creating an increasingly corrosive environment that threatens your entire fuel system.

Contaminated fuel can lead to complete generator failure during critical moments, risking operations and safety.

If you have clogged filters or failed labs, Contact Us for rapid response

We offer a range of services to tackle any fuel problem.

We provide definitive insights into your fuel and tank conditions through comprehensive sampling and certified laboratory testing.

Our specialized treatment programs eliminate existing contamination and prevent future microbial growth, protecting your investment.

Regular testing and maintenance ensure your backup power systems remain reliable and ready when you need them most.

In many cases, we can provide rapid response using a combination of our expert field technicians and partners where needed.

Every drop of fuel tells a story. Our systematic approach combines historical analysis, visual inspection, and advanced testing protocols to ensure nothing is overlooked.

Advanced technology meets meticulous attention to detail.

FuelCare delivers the industry’s most comprehensive digital reporting, providing clear, photo-documented evidence of your fuel system’s health within 2 business days of service.

Access your complete maintenance history, compliance status, and trending analysis anytime through our secure client portal – because when power matters, documentation matters.

FuelCare offers testing that meets or exceeds Fuel Industry Standards.

Our clients choose the testing standards.

Field techs professionally pull a sample, perform a visual analysis with recommendations, generate a report and if requested, send fuel samples to specialized third-party labs.